We are LEAN aware

We are familiar with the notions of the Lean Manufacturing philosophy, which allows us to provide our Clients with even better products that meet the requirements set by the present times.

In creating optimal solutions, we are assisted by the knowledge of notions such as SMED (already at the design stage we optimize changeover times) or TPM (selecting components we pay attention to durability or ease of replacement of individual elements).

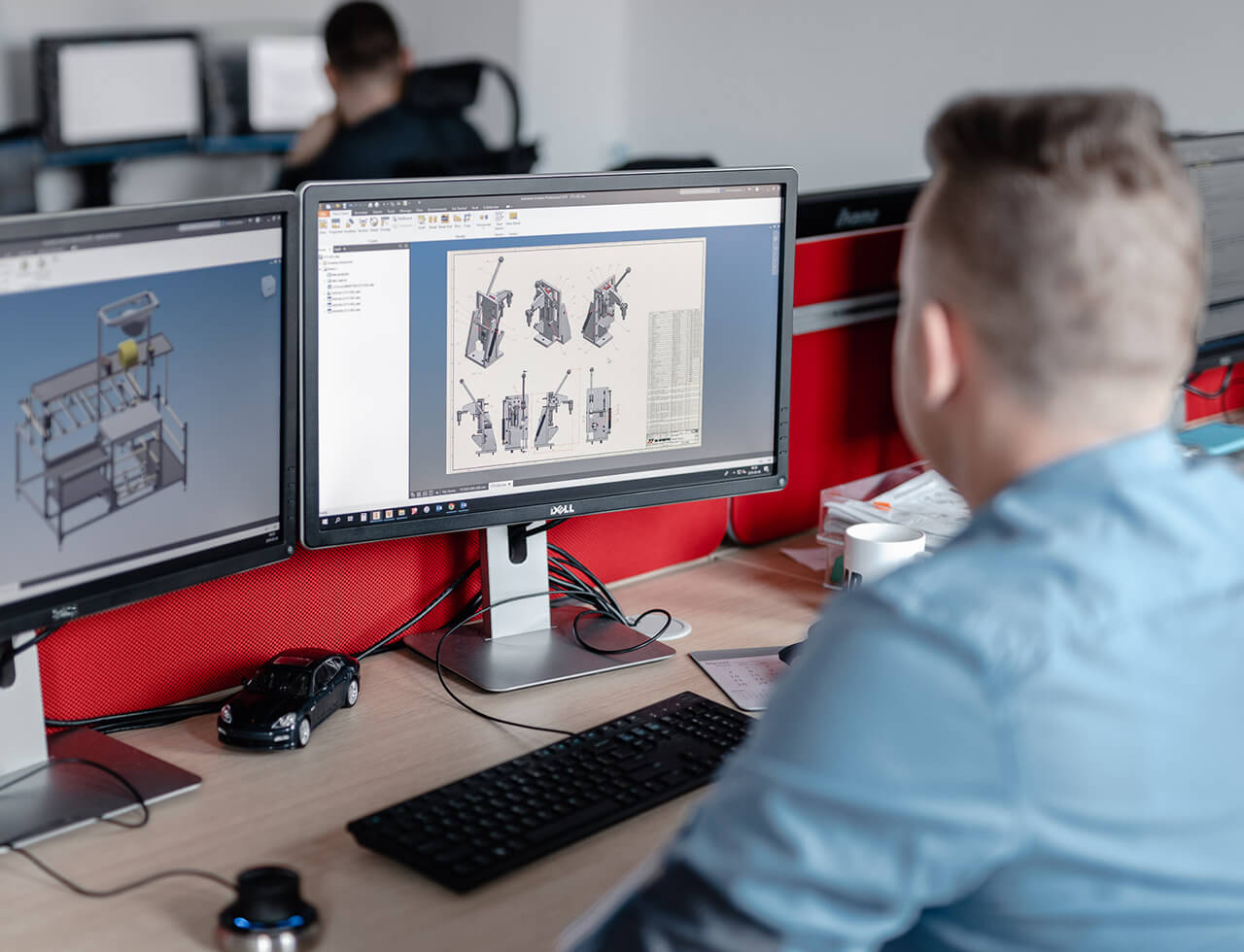

We design processes from scratch

When designing machines for our Clients’ processes, we rely on their assumptions or plan from scratch. We recognize great importance in ensuring that our devices are optimally adapted to the needs of our Clients.

On request, we can also go further and analyze the entire value stream in the company using the VSM method. This will allow us to have a broader perspective and propose the most optimal solutions reducing production costs.

The analysis of manual and machine cycle times

We specialize not only in fully automated processes, but also in semi-automatic and manual processes, in which the operator cooperates with the machine and often determines its efficiency.

As one of the few on the market, we can offer the Client the most accurate analysis of elementary movements (MTM and RWF methodology). We precisely define the time of cycles of activities performed by the operator. This, combined with the analysis of machine cycles, allows for optimal organization of the machines and employees work. Precise analysis and awareness of losses that occur in production processes enables us to effectively eliminate them.

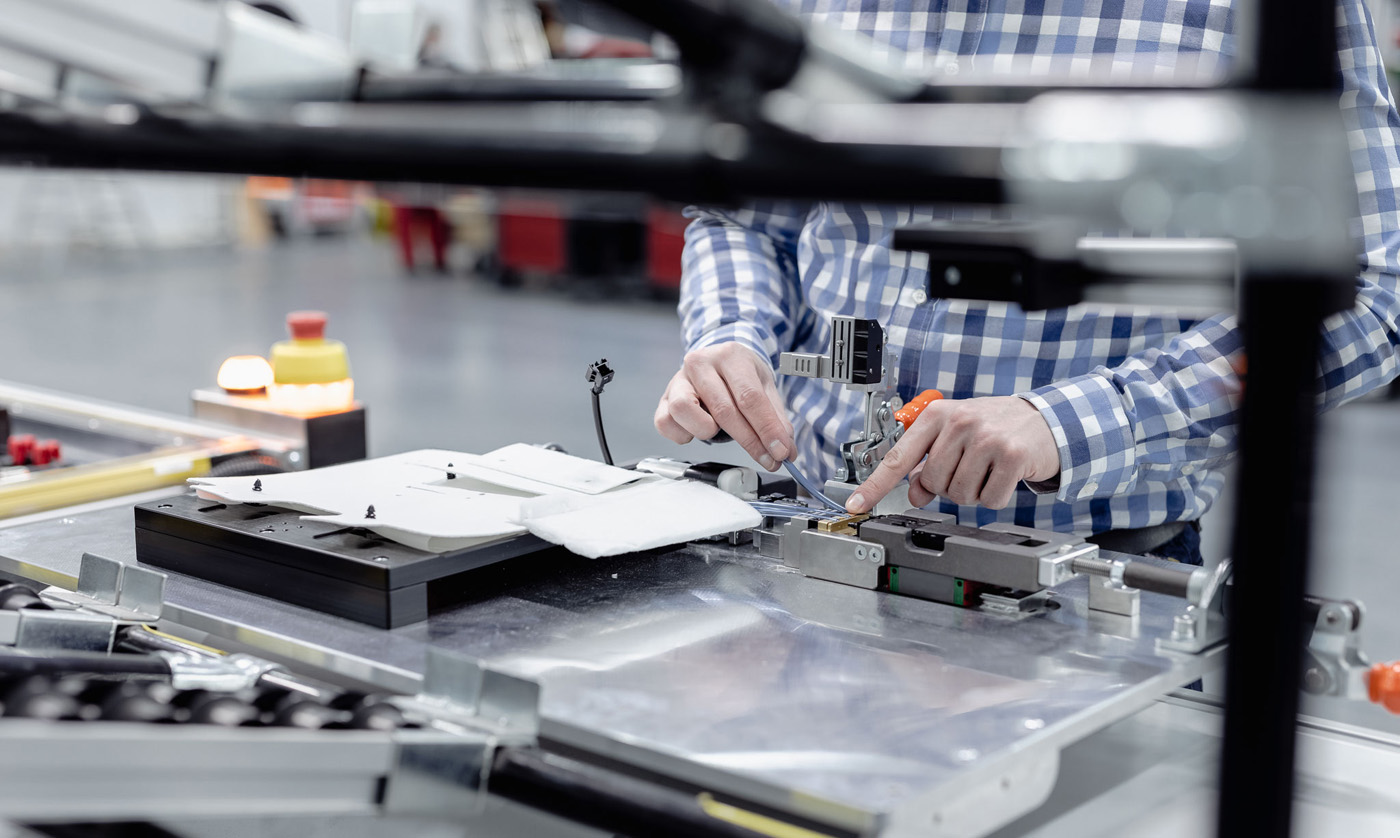

Ergonomics and delivery of components

When designing lines, we always carefully analyze the ergonomics of the operator’s workplace. It is extremely important for the employee to feel comfortable so that their movements are natural and free, while the tools and components are within their reach.

Space for production materials is prepared in such a way that it is possible to easily implement the components delivery system. We also optimize them for stocks available on the line, depending on the material delivery frequency used by the Client.

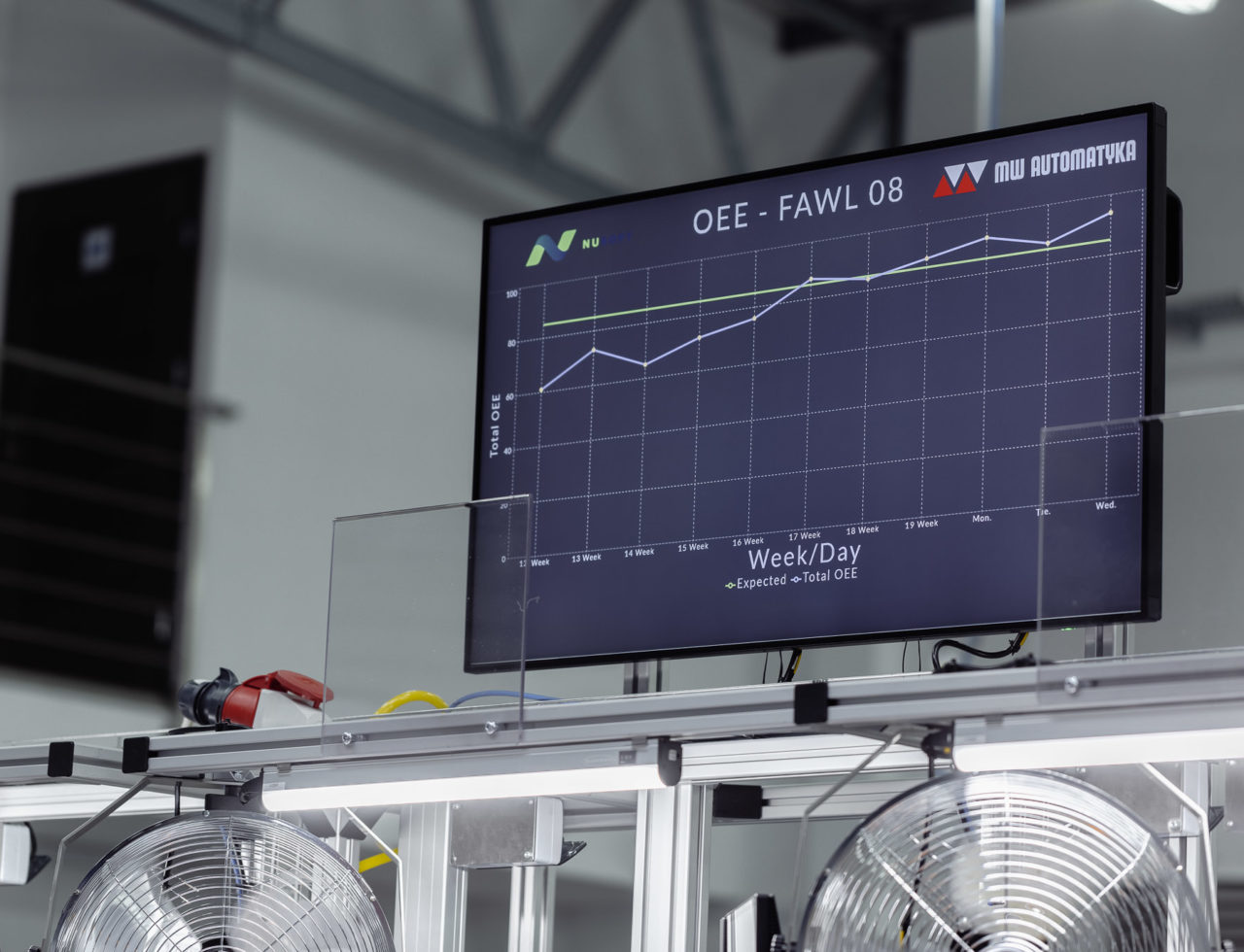

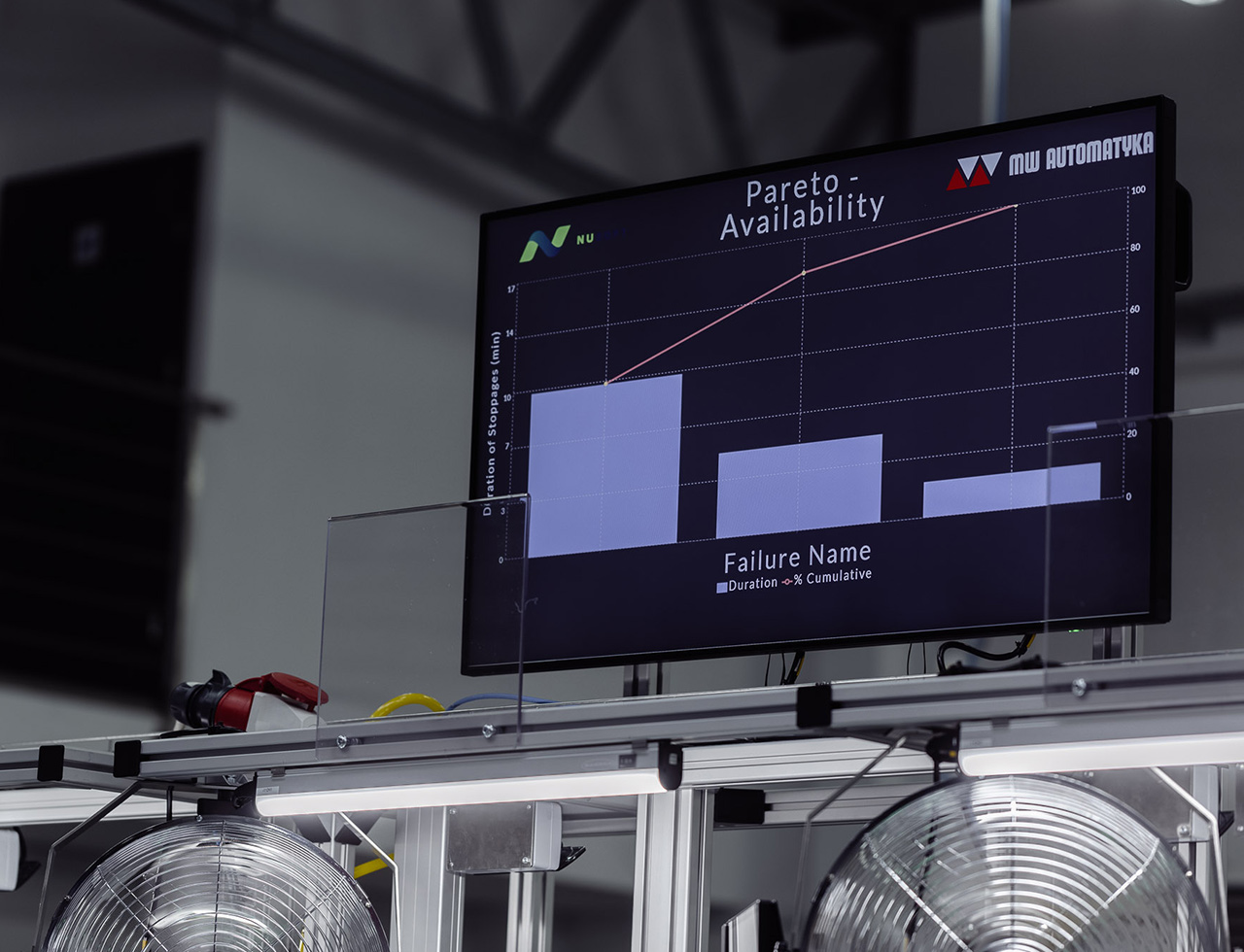

Visual Management

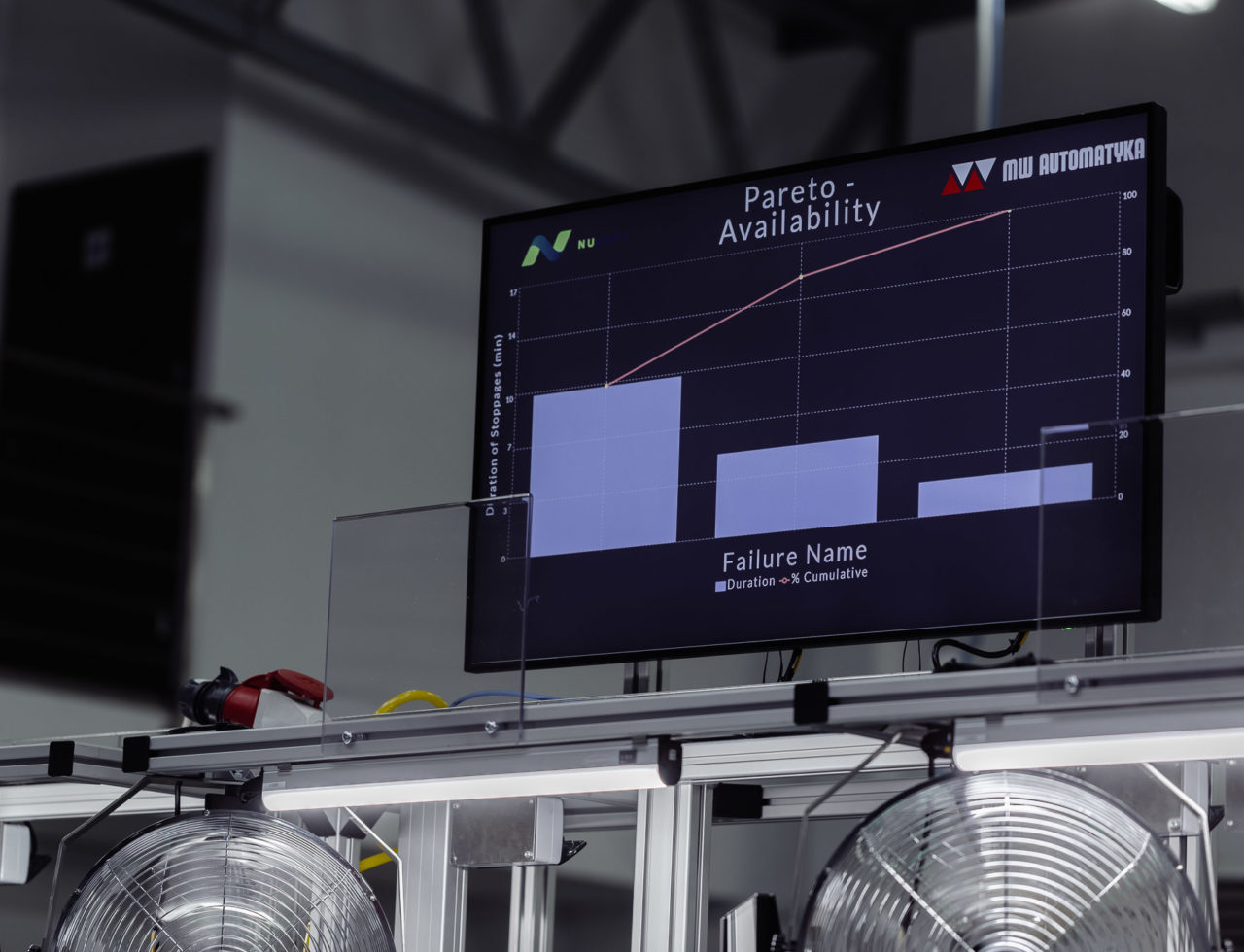

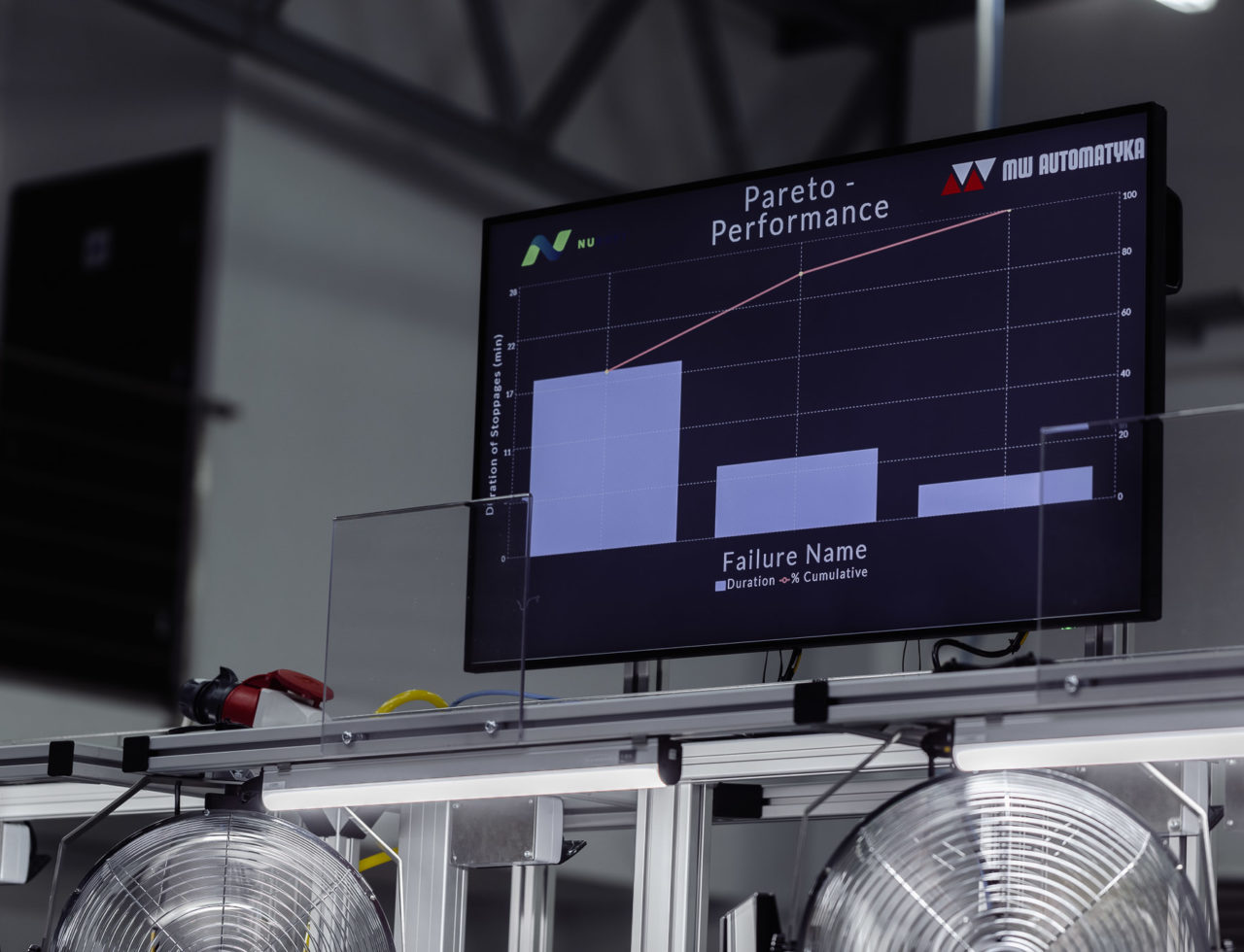

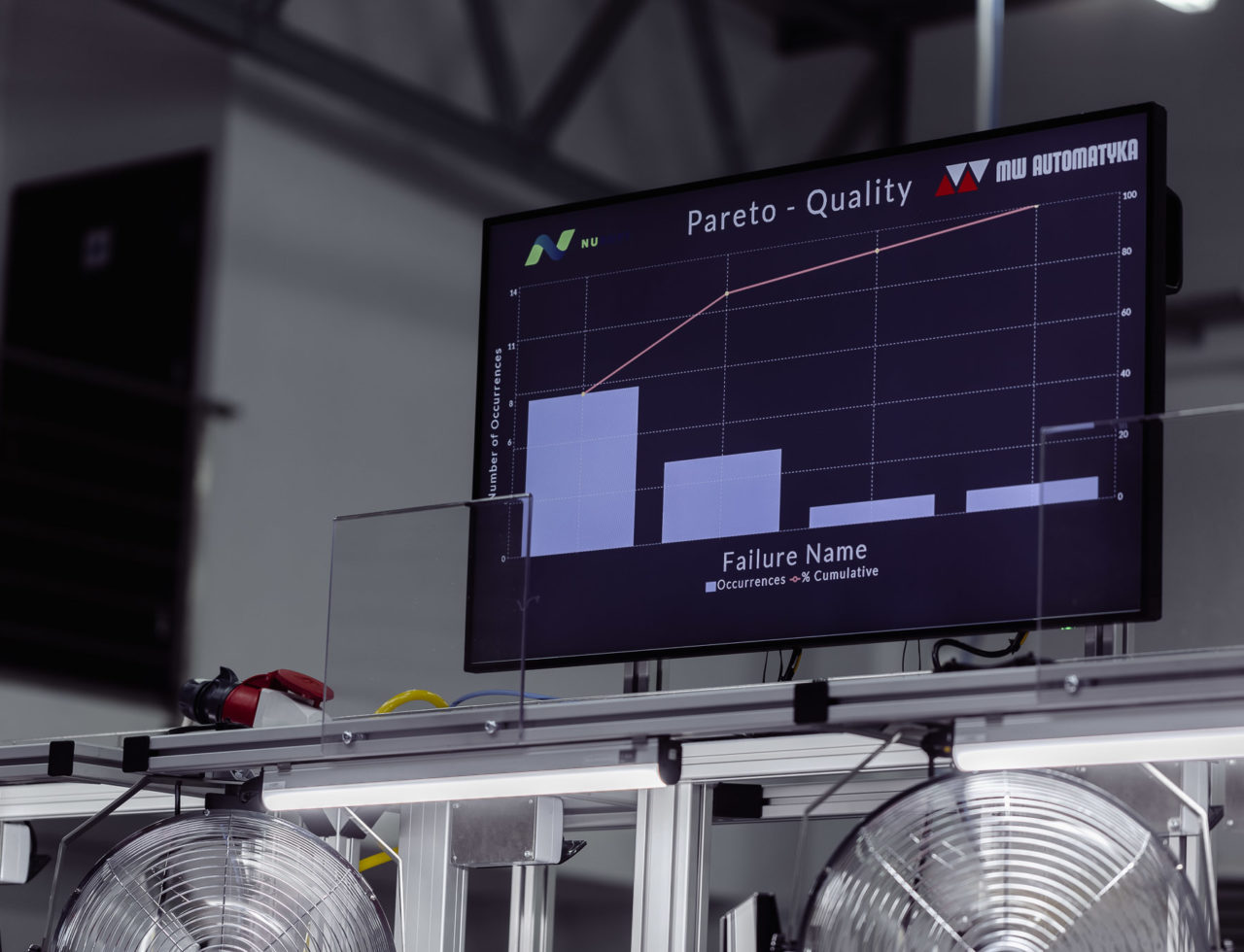

We understand how important Visual Management is in the present times and that with the current pace of work, the site manager has only a few moments to assess whether a given machine works with the assumed efficiency so that the product reaches the Client in the set amount and time. We improve and develop this aspect of our products. The most important information is to be available in a transparent way and at first glance.

More detailed information on the number of individual defects, length of downtime and losses related to cycle times are available from the web platform level, or after switching to the appropriate screen. Automatic collection and transparent presentation of data available on the line enables fast analysis and allows for effective corrective and preventive actions.

Visualization - work station

We do not focus only on information for managers or engineers in a given area, but also on a person working on a given station. On request, our lines are equipped with automatically changing work instructions (depending on the reference produced at the time). The position documentation is loaded from the level of the web platform – say goodbye to paper versions which make it difficult to control the appropriate revision and to the time devoted to make changes in documentation during changeover.

Our solutions also help to control the right cycle time on manual and semi-automatic lines. Each operator can see if their work pace rate is consistent with the assumed one because each cycle is measured, while the operator gets a simple visual information about the results of their work.